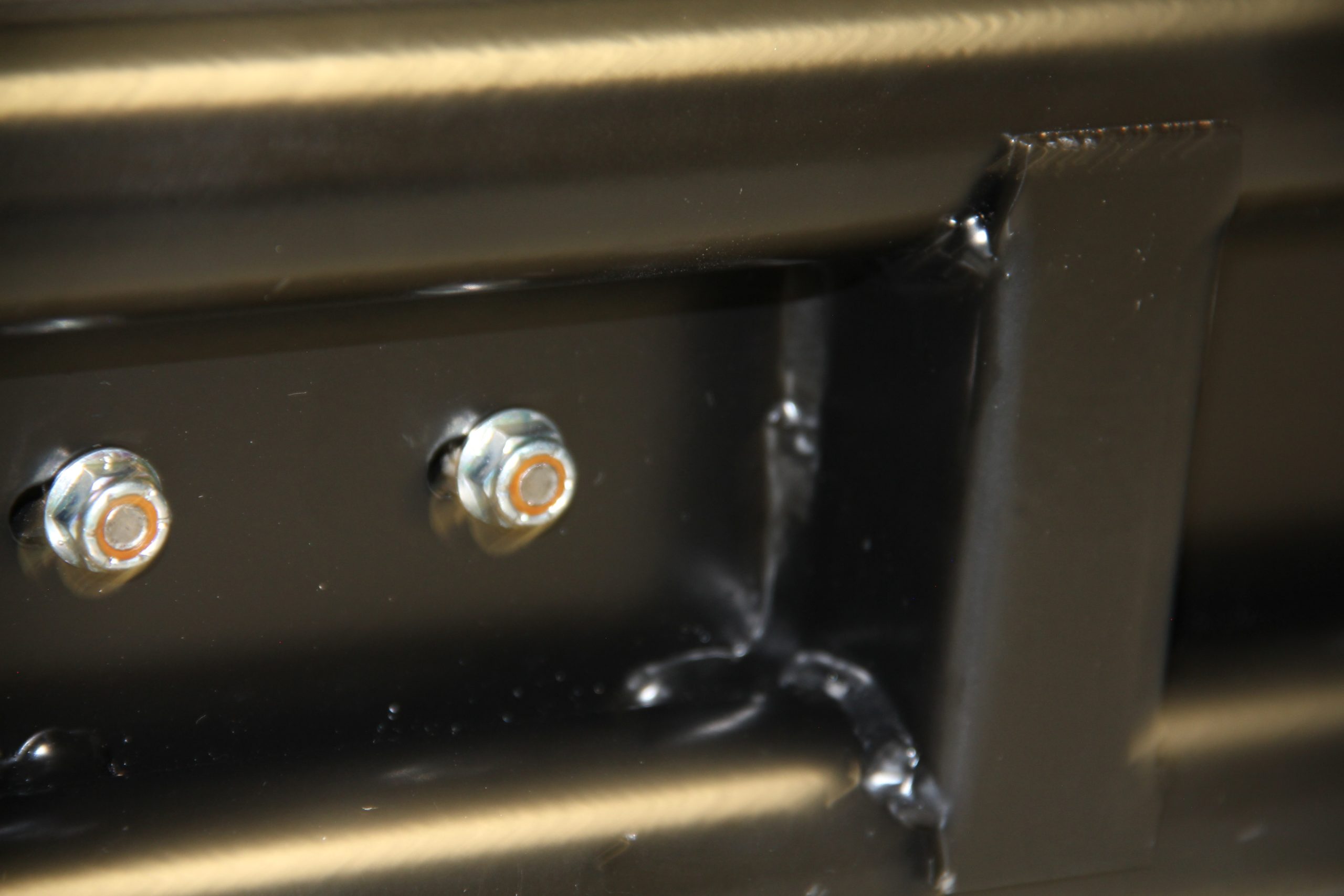

Welding

Value Added Welding Services

Rapid Weld Fixture design and certified welding in high, medium and low volume to fit all types of welding needs.

Seeking a metal fabrication collaborator who can quickly and accurately weld to your specifications?

Welding Capabilities

No two projects are alike & that’s why we invest in new technology and commit to the most effective production methods, ensuring the perfect welding solution for every job.

METAL INERT GAS (MIG) WELDING: Known for its speed and adaptability, MIG welding is one of the most common industrial welding processes. With MIG Welding Quest ensures a strong and complete weld that meets the highest standards of quality and durability.

RESISTANCE METAL WELDING: Quest Metal Products employs resistance welding, leveraging pressure and localized heat to effectively fuse metal parts. This efficient process not only ensures strong, lasting welds but also eliminates the need for extra materials, making it a cost-effective solution for your welding needs.

Tungsten Inert Gas (TIG) Metal Welding: TIG welding, also called (GTAW), is a precise method using tungsten electrodes to weld metals. It’s great for thin stainless steel, aluminum, and other alloys, offering better control for stronger welds.

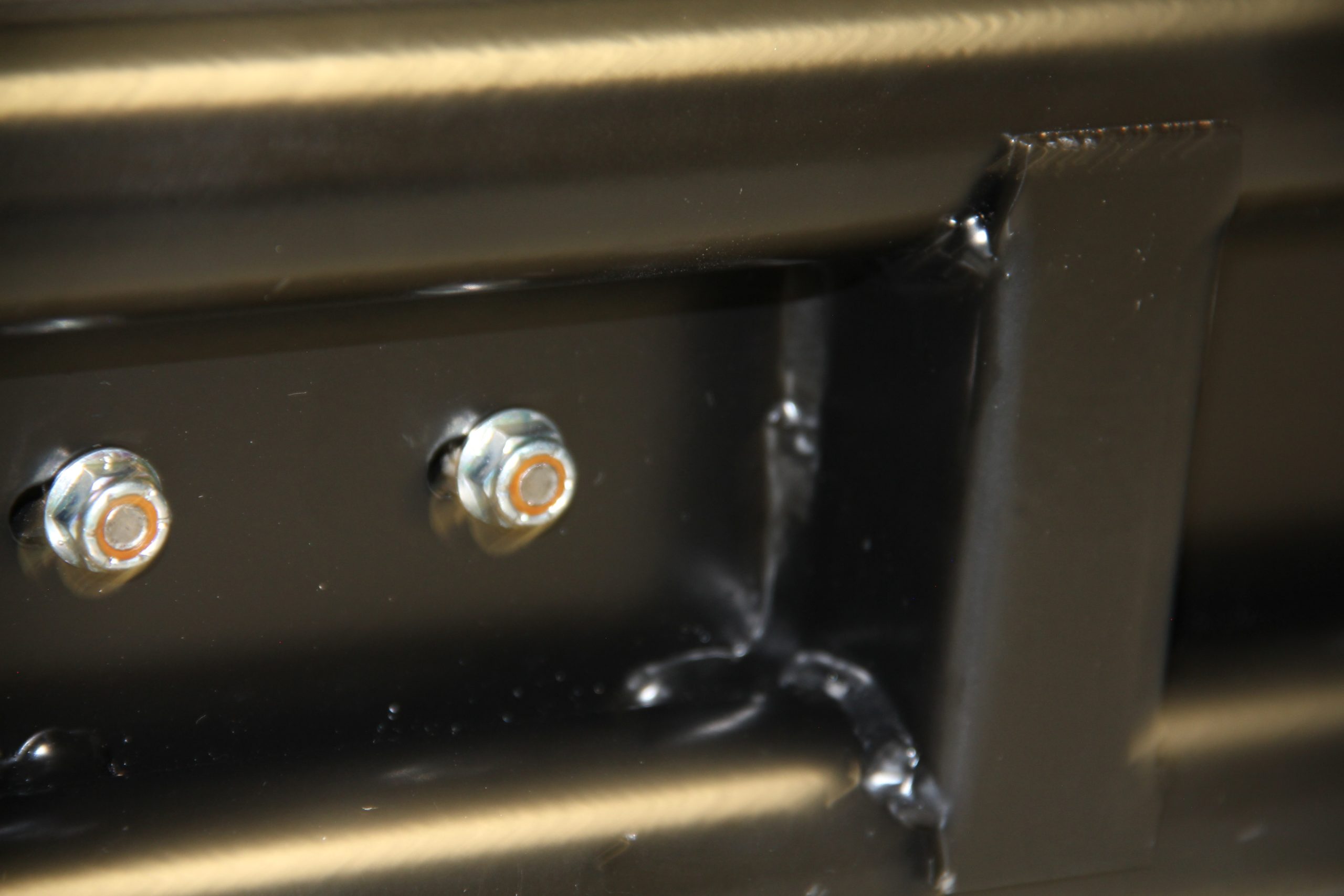

Value Added Welding Services

With Multiple Manual Welding Stations specific for both High and Low Volume Output. Quest Metal Products has the capacity and capabilities to handle all types of welding needs.

Seeking a metal fabrication collaborator who can quickly and accurately weld to your specifications?

Welding Capabilities

No two projects are alike & that’s why we invest in new technology and commit to the most effective production methods, ensuring the perfect welding solution for every job.

METAL INERT GAS (MIG) WELDING:

Known for its speed and adaptability, MIG welding is one of the most common industrial welding processes. With MIG Welding Quest ensures a strong and complete weld that meets the highest standards of quality and durability.

RESISTANCE METAL WELDING:

Quest Metal Products employs resistance welding, leveraging pressure and localized heat to effectively fuse metal parts. This efficient process not only ensures strong, lasting welds but also eliminates the need for extra materials, making it a cost-effective solution for your welding needs.

TUNGSTEN INERT GAS (TIG) METAL WELDING:

TIG welding, also called (GTAW), is a precise method using tungsten electrodes to weld metals. It’s great for thin stainless steel, aluminum, and other alloys, offering better control for stronger welds.